June 4, 2023 | Chris Corley

Corks!

Recently, I was honored to be invited on a trip to Portugal by Cork Supply one of our cork suppliers. We traveled to the cork forests in the south of Portugal to see the harvest, then up to Porto to visit the cork processing facilities,and then over to the Rioja region in Spain to visit their tin capsule processing facilities. Along the way, we were able to visit some terrific wineries and restaurants in the Douro Valley, Portugal and in Rioja, Spain. We were a group of about 8 winemakers, and it was a lot of fun, very educational, and a terrific way for us to meet the growers, processors, people and families behind some of our most critical packaging supply elements ... our closures. Natural Cork & Tin Capsules.

I'm excited to share my trip in a series of blog posts that I'll roll out over the next week or so. So stay tuned! Today, we'll talk about the cork forests, the trees and the harvest process!

THE FOREST FOR THE TREES

The all-natural cork we use at MONTICELLO is grown mainly in the Iberian Peninsula, in the southern half of Portugal, and some in Spain. While the cork forests cover large swaths of land in southern Portugal, the team in charge of selection is extremely knowledgable about each forest and grower and has a thorough understanding of the soils and any other activities on the property.

For example, Director of Raw Materials Frederico Lima Mayer tends away from forests that have livestock, since the animals will rub up against the trees and can affect the quality of the resulting cork bark.

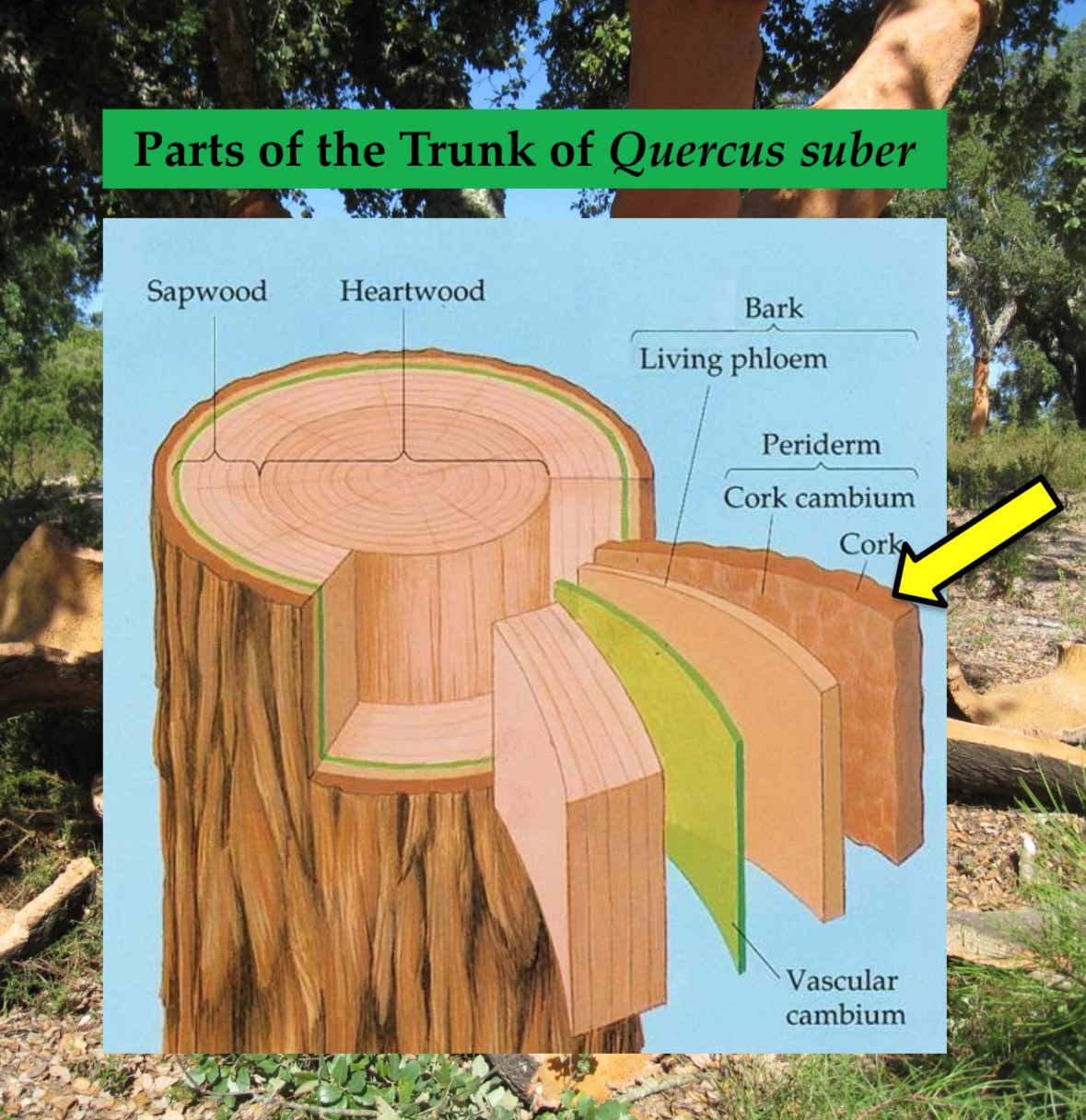

The cork oak tree is unique in its ability to grow very thick bark, which is actually how the cork is harvested from the tree. A cork oak tree must be 25 years old before it can be harvested for the first time. After that, the bark can only be harvested every 9 years.

The trees are grown from acorns, whcih are carefully selected, and the forests are laid out very naturally. The trees are not linear, or lined up like we do with vineyards, they're just naturally laid out through the forest, with lots of open space. It is quite an idyllic environment, and I'm glad our corks grow in such a happy place before they seal up our bottles of wine!

THE GROWERS

Given the incredibly long time frames involved, growing cork is a multi-generational activity, and typically trees are planted with the next generations in mind. This really resonated with me, coming from a multi-generational, family-owned wine business. The grower we visited was fourth generation on their property, each generation contributing to the next. Wonderful!

HARVESTING THE CORK

As a closure for wine, natural cork is extremely environmentally friendly. The trees can live for 200+ years, since only the cork bark is stripped from the lower 1/2 of the tree to provide the raw material for wine cork production. The cork bark is stripped from the tree by men with axes, known as 'strippers'. Typically they work in pairs, and they can strip down a good size tree in a matter of minutes. Then that tree will reside peacefully and undisturbed for nine years before being harvested again.

THE PEOPLE

For such a critical element in preserving the quality of our best wines, the growing and harvesting process is incredibly low-tech, very natural, and entirely manual. What really showed in our visit to the cork forest was the thoughtfulness and utter dedication to quality from everyone on the team ... from the growers, to the Frederico and his team of quality controllers, all the way to the guys loading the trucks to take the raw bark to the facility near Lisbon. Wonderful!

*A big thank you to the entire team at Cork Supply, for making this trip possible, and for dedicating such effort to the quality of their natural corks.

NEXT POST : Stay tuned for the next blogpost featuring the next steps of cork quality sorting, aging, and preparations for the next phase of processing!